Sanitary Vertical Tanks for Beverage

| Availability: | |

|---|---|

| Quantity: | |

Product Overview

Sanitary Vertical Tanks for Beve are hygienic storage solutions designed exclusively for the beverage industry, including applications such as juice, beer, wine, mineral water, and carbonated drinks. Constructed from 304 stainless steel (for standard beverages) or 316L stainless steel (for acidic beverages like citrus juice), these tanks comply with FDA 21 CFR Part 177 and EU Regulation 10/2011 for food contact materials. The vertical orientation maximizes vertical space utilization, with standard capacities ranging from 500 L to 20,000 L and custom options up to 50,000 L for large-scale bottling plants. Key features include a polished inner surface (Ra < 0.8 μm), a conical or flat bottom (for easy drainage), and integrated CIP connections, ensuring no residue buildup and maintaining beverage quality. The tanks operate at atmospheric pressure (standard) or can be designed for slight positive pressure (up to 2 bar) for carbonated beverage storage.

Product Features

• Hygienic Material & Finish: The inner tank is made of 304/316L stainless steel with a mechanical polish (Ra < 0.8 μm) or electropolish (Ra < 0.4 μm) finish, eliminating bacterial hiding spots and ensuring easy cleaning. The outer surface is powder-coated (RAL 9002 white) for rust resistance and a professional appearance.

• Space-Efficient Vertical Design: The vertical structure reduces floor space usage by 50–70% compared to horizontal tanks, making it ideal for beverage facilities with limited ground area. Optional stackable designs (for small-capacity tanks, 500–2000 L) further optimize space.

• Complete Drainage System: The tank bottom features a 3°–5° slope (conical bottom) or a flat bottom with a central drain port (diameter: 50–100 mm), ensuring complete drainage of beverages (no residual liquid >50 mL) to prevent spoilage and cross-contamination.

• Integrated Sanitary Components: Equipped with a sanitary manhole (diameter: 400–600 mm) with a tri-clamp connection, a level sensor (ultrasonic or capacitance type, accuracy: ±1% of full scale), and CIP spray balls (360° coverage) to automate cleaning cycles.

• Temperature Control Options: For temperature-sensitive beverages (e.g., craft beer, fresh juice), an optional jacket (water or glycol) surrounds the tank, allowing precise temperature control (2°C–25°C) with a temperature fluctuation of ±0.5°C.

Applications

• Fruit Juice & Smoothie Industry: Stores freshly squeezed orange juice, apple juice, and berry smoothies at 4°C–8°C (via jacketed cooling) to preserve vitamins and prevent microbial growth, with 316L stainless steel resisting acidic corrosion.

• Craft Beer & Brewing Industry: Used as bright tanks (for post-fermentation storage) to clarify beer and carbonate it (at 1–2 bar pressure), with a polished inner surface preventing beer stone buildup (calcium oxalate deposits).

• Mineral Water & Bottled Water Industry: Holds purified mineral water before bottling, with atmospheric pressure design and CIP cleaning after each batch to maintain water purity (total dissolved solids <500 mg/L).

• Wine Industry: Serves as fermentation tanks (for red wine) or aging tanks (for white wine), with jacketed heating/cooling to control fermentation temperature (20°C–30°C for red wine, 10°C–15°C for white wine) and enhance flavor development.

FAQ

Q1: What is the maximum capacity of Sanitary Vertical Tanks for Beve?

A1: Standard capacities go up to 20,000 L, but custom tanks can be built up to 50,000 L with reinforced walls (thickness: 6–10 mm) to support the weight of large beverage volumes.

Q2: Can the tank be used for carbonated beverages (e.g., soda, sparkling water)?

A2: Yes. The pressure-rated model (up to 2 bar) features a sealed top, pressure relief valve, and reinforced tank walls to safely store carbonated beverages without gas leakage.

Q3: How long does a CIP cycle take for the tank?

A3: A standard CIP cycle (pre-rinse, detergent wash, post-rinse, sanitization) takes 30–60 minutes, depending on tank size. The integrated CIP spray balls ensure 100% coverage, eliminating the need for manual scrubbing.

Q4: Is the tank compatible with automated filling lines?

A4: Yes. The tank’s bottom drain port is designed with tri-clamp or flange connections (per industry standards) that can be directly connected to filling line pumps, enabling a seamless transfer of beverages with minimal product loss (<1%).

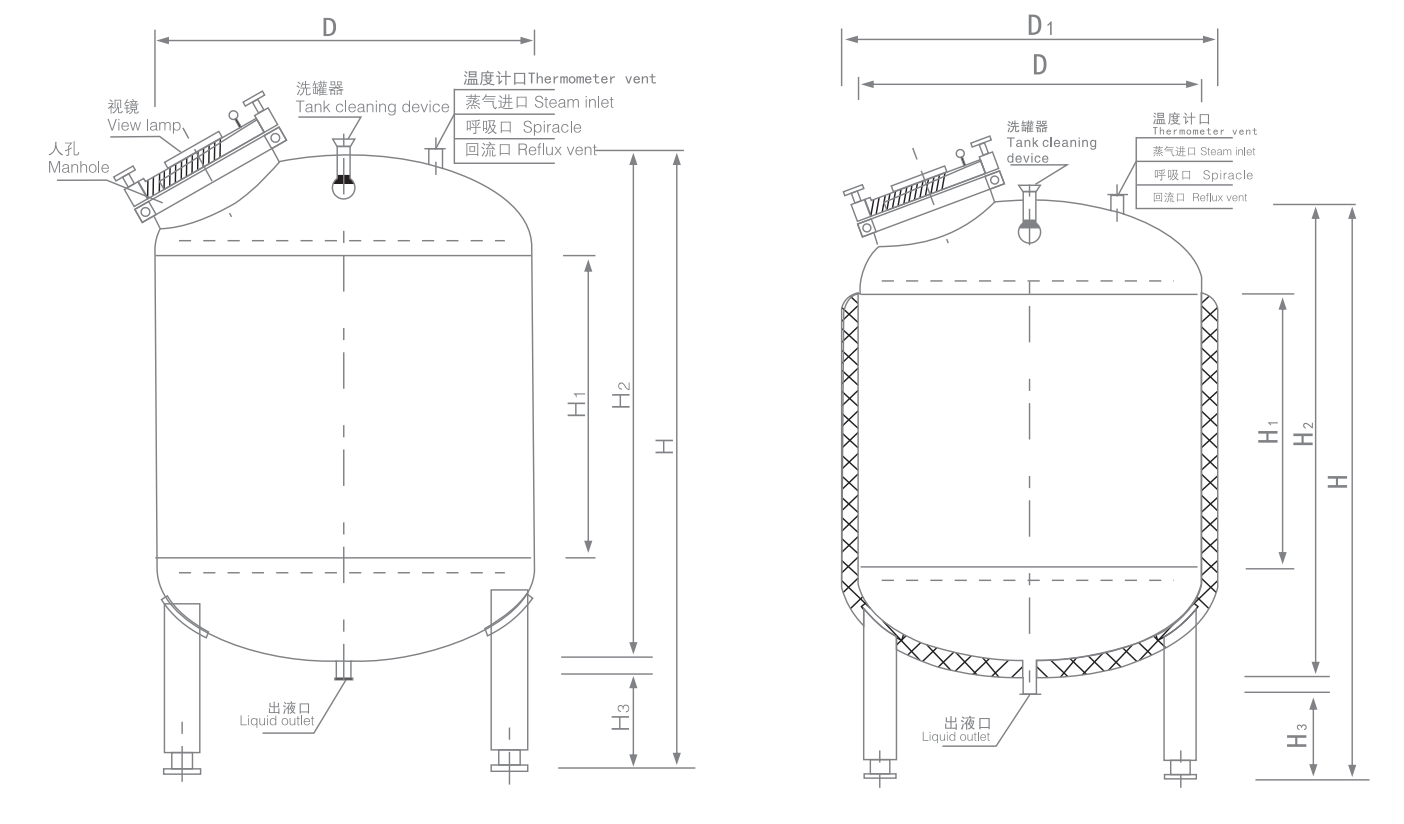

| Specification(L) | Reference size(mm) | ||||||

| D | D1 | H1 | H2 | H3 | H | DN | |

| 200 | 700 | 800 | 400 | 800 | 235 | 1085 | 32 |

| 250 | 800 | 900 | 400 | 850 | 235 | 1135 | 32 |

| 300 | 800 | 900 | 460 | 910 | 235 | 1195 | 32 |

| 500 | 900 | 1000 | 640 | 1140 | 270 | 1460 | 40 |

| 600 | 900 | 1000 | 830 | 1130 | 270 | 1450 | 40 |

| 800 | 1000 | 1100 | 880 | 1430 | 270 | 1750 | 40 |

| 1000 | 1100 | 1200 | 880 | 1480 | 270 | 1800 | 40 |

| 1200 | 1100 | 1200 | 1100 | 1700 | 270 | 2020 | 40 |

| 1500 | 1200 | 1300 | 1150 | 1800 | 270 | 2120 | 40 |

| 2000 | 1400 | 1500 | 1220 | 1970 | 280 | 2300 | 40 |

| 2500 | 1500 | 1600 | 1150 | 1980 | 280 | 2310 | 40 |

| 3000 | 1600 | 1700 | 1220 | 2120 | 280 | 2450 | 40 |

| 4000 | 1800 | 1900 | 1250 | 2250 | 280 | 2580 | 40 |

| 5000 | 1900 | 2000 | 1500 | 2550 | 320 | 2950 | 50 |

| 7000 | 2200 | 2300 | 1450 | 2650 | 320 | 3050 | 50 |

| 8000 | 2200 | 2300 | 1750 | 2950 | 320 | 3350 | 50 |

1

1. What's the company nature?

We are the manufacturer, source factory, that with over 20 years experience on stainless steel products.

2. Are there OEM & ODM services?

Yes, OEM & ODM orders are welcomed.

3. How's the delivery time?

It depends on the design and quantity of the products, 20-50 days usually.

4. What's the MOQ?

MOQ is one set, the more the quantity, the better the price.

5.How to confirm my product?

Our engineers will make the drawings for your conformation.