Compliant Manufacturing and Quality Assurance

Custom 200-8000L Volumes for Diverse Needs

Premium Stainless Steel with Precision Components and Mirror Finish

1. These storage tanks are manufactured, tested for pressure, and accepted in accordance with 《Steel Pressure Vessels》 and 《Steel Chemical Manufacturing Technology Requirements》.

2. Storage tank volumes range from 200L to 8000L (other standard specifications can be custom-designed and processed according to customer needs).

3. Primary applications include storing large-volume infusions, water for injection, oral solutions, and deionized water (purified water).

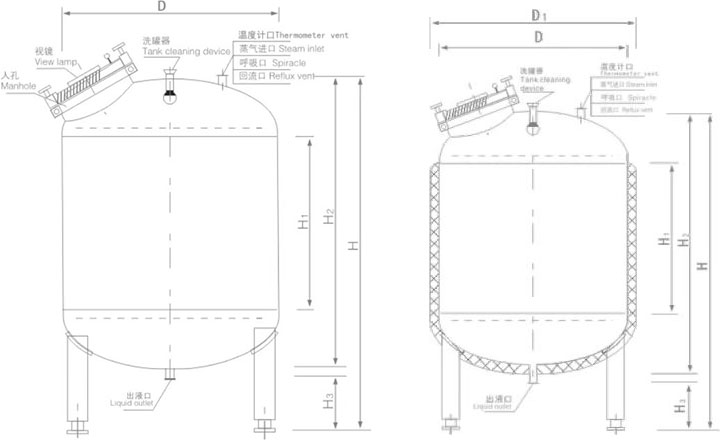

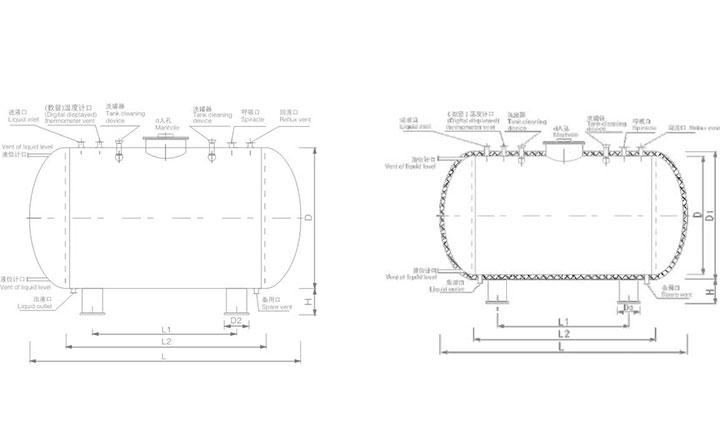

4. Tank configurations include precision level gauges, breathing apparatuses, lamp mirrors, tank washing devices, manholes/hand holes, digital thermometers, and multiple quick-connect interfaces.

5. Tanks feature common ISO-standard fast-loading reels. Tank plates are made of imported 316L or 304 stainless steel:

• Inner surface: mirror-polished to a Ra 0.28–0.45 μm finish

• Outer surface: mirror-finished (imported 304) or matte-treated

|

|

|

|

| Specification(L) | Reference size(mm) | ||||||

| D | D1 | H1 | H2 | H3 | H | DN | |

| 200 | 700 | 800 | 400 | 800 | 235 | 1085 | 32 |

| 250 | 800 | 900 | 400 | 850 | 235 | 1135 | 32 |

| 300 | 800 | 900 | 460 | 910 | 235 | 1195 | 32 |

| 500 | 900 | 1000 | 640 | 1140 | 270 | 1460 | 40 |

| 600 | 900 | 1000 | 830 | 1130 | 270 | 1450 | 40 |

| 800 | 1000 | 1100 | 880 | 1430 | 270 | 1750 | 40 |

| 1000 | 1100 | 1200 | 880 | 1480 | 270 | 1800 | 40 |

| 1200 | 1100 | 1200 | 1100 | 1700 | 270 | 2020 | 40 |

| 1500 | 1200 | 1300 | 1150 | 1800 | 270 | 2120 | 40 |

| 2000 | 1400 | 1500 | 1220 | 1970 | 280 | 2300 | 40 |

| 2500 | 1500 | 1600 | 1150 | 1980 | 280 | 2310 | 40 |

| 3000 | 1600 | 1700 | 1220 | 2120 | 280 | 2450 | 40 |

| 4000 | 1800 | 1900 | 1250 | 2250 | 280 | 2580 | 40 |

| 5000 | 1900 | 2000 | 1500 | 2550 | 320 | 2950 | 50 |

| 7000 | 2200 | 2300 | 1450 | 2650 | 320 | 3050 | 50 |

| 8000 | 2200 | 2300 | 1750 | 2950 | 320 | 3350 | 50 |

Food and beverage: preheating and mixing of dairy products, dissolution of juice syrup.

Pharmaceutical and chemical: oral liquid preparation, ointment matrix emulsification.

Bioengineering: fermentation medium preparation, sterile storage.

Provide full-process customization services, from laboratory-level precision equipment to industrial large-scale tanks, to meet different production capacity and process requirements.

GET A QUOTE