ASME and GMP Certified

Precision Temperature/Pressure Control

Multi-Industry Solutions

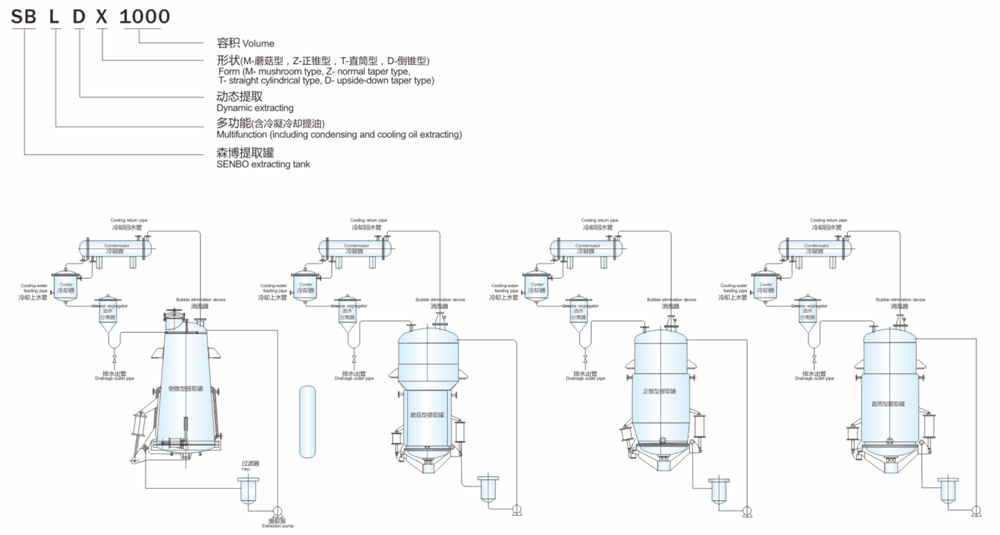

Extracting the active ingredients by utilizing temperature variations, our extraction vessels feature a SUS304/16L stainless steel liner for superior corrosion resistance. Dual-mode jackets support vacuum insulation (-80°C) or hot fluid circulation (150°C) for precise control during extraction, storage, and recovery. GMP-compliant designs feature fast cleaning and easy maintenance, making them ideal for pharmaceutical, chemical, and research applications.

Capacity: 60L~11000L

Design pressure in tank: 0.09 Mpa

Design pressure in jacket: 0.3 Mpa

Design temperature in tank: -80°C~150°C

Design temperature in jacket: -80°C~150°C

1 x 6-inch ferrule opening

2 x 1.5-inch tri-clamp sight glasses

2 x 1/2-inch FNPT coils

1 x 1/2-inch FNPT dip tube

3 x 1/2-inch FNPT steam interfaces

1 x 1/4-inch FNPT interface

1 x 1/2-inch FNPT interface (top)

1 x 1/2-inch FNPT interface (bottom)

|

Model |

SB-0.5 |

SB-1 |

SB-2 |

SB-3 |

SB-4 |

SB-6 |

SB-8 |

SB-10 |

|

Volume (L) |

600 |

1200 |

2300 |

3200 |

4300 |

6300 |

8500 |

11000 |

|

Design pressure in tank (Mpa) |

0.09 |

|||||||

|

Design pressure of interlayer (Mpa) |

0.3 |

|||||||

|

Feed port diameter (mm) |

400 |

400 |

400 |

400 |

500 |

500 |

500 |

500 |

|

Heating area (㎡) |

2.4 |

3 |

4.7 |

6.8 |

8 |

10 |

12 |

12 |

|

Condensation area (㎡) |

3 |

4 |

5.4 |

8 |

10 |

10 |

15 |

18 |

|

Cooling area (㎡) |

1 |

1 |

1 |

1 |

1 |

2.2 |

2.2 |

3 |

|

Filtering area (㎡) |

0.25 |

0.25 |

0.25 |

0.25 |

0.25 |

0.30 |

0.30 |

0.30 |

|

Diameter of slag discharge door (mm) |

600 |

800 |

1000 |

1200 |

1200 |

1400 |

1500 |

1600 |

|

Steam consumption (kg/h) |

285 |

285 |

346 |

570 |

660 |

718 |

903 |

1140 |

|

Water consumption (T/h) |

2.1 |

2.1 |

2.5 |

4.2 |

4.5 |

5.5 |

6.7 |

6.7 |

|

Heating steam pipe opening (mm) |

32 |

32 |

32 |

40 |

40 |

50 |

50 |

50 |

|

Exhaust pipe opening (mm) |

100 |

100 |

100 |

125 |

125 |

150 |

150 |

150 |

|

Cooling water pipe opening (mm) |

40 |

40 |

40 |

50 |

50 |

50 |

65 |

70 |

|

Motor power (KW) |

2.2 |

2.2 |

3 |

4 |

5.5 |

5.5 |

7.5 |

7.5 |

|

Stirring speed (r/min) |

36 |

36 |

36 |

36 |

36 |

36 |

36 |

36 |

GET A QUOTE