Stainless Steel Vacuum Evaporator adopts a variety of energy-saving technologies and optimized designs to effectively reduce energy consumption and operating costs. The evaporator has an efficient heat conduction system and insulation measures to reduce heat loss. It is widely used in various industries and creates huge energy-saving benefits for customers.

Applicable to low temperature vacuum concentration of heat sensitive materials, especially applicable to concentration of traditional Chinese medicine, westem medicine, starch sugar and other water solution.

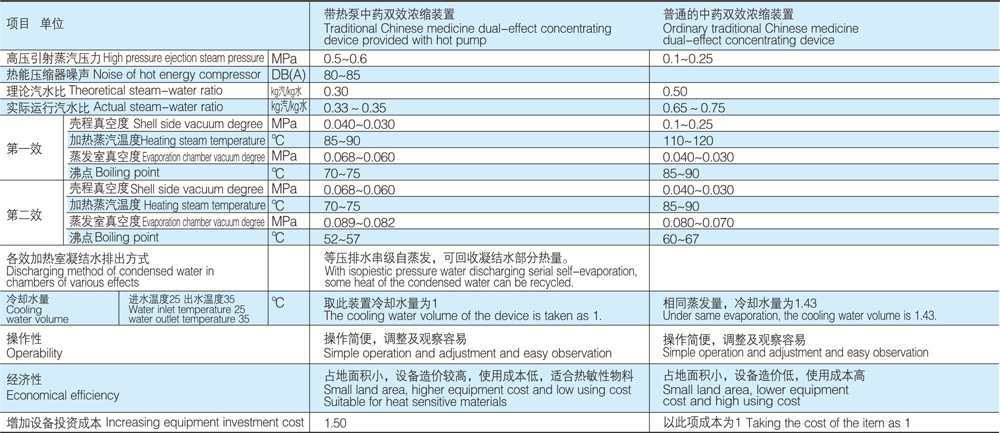

After being compressed through hot pump, the first-efiect secondary steam is supplied to the first-effect heating, so that large amount of steam is saved and producton oost is reduced.

First-effect heater,frst-effect evaporation chamber. hot pump, second-effect heater, second-elfect evaporalion chamber, condenser, liquid receiving tank, a set of pipe and valve in the system.

1.Volume of extract can: 1m³,2m³, 3m³, 6m³

2.Volume of concentrator: 0.5m³, 1m³, 1.5m³.2.5m³

3.Temperature for water distillation: 90~1009℃

4.Temperature for alcohol distillation: 78~83℃

5.Distillation time: 4~5HB

6.Vacuum degree: 0.05-0.08MPa

7. Used pressure: 0.08~0.2MPa

GET A QUOTE